Does the 30HP Micro-Oil Twin Screw Single Stage Compressor Have a Low-Vibration Base or Overall Shock Absorption Design?

Structural Foundation Considerations in Industrial Compressor Design

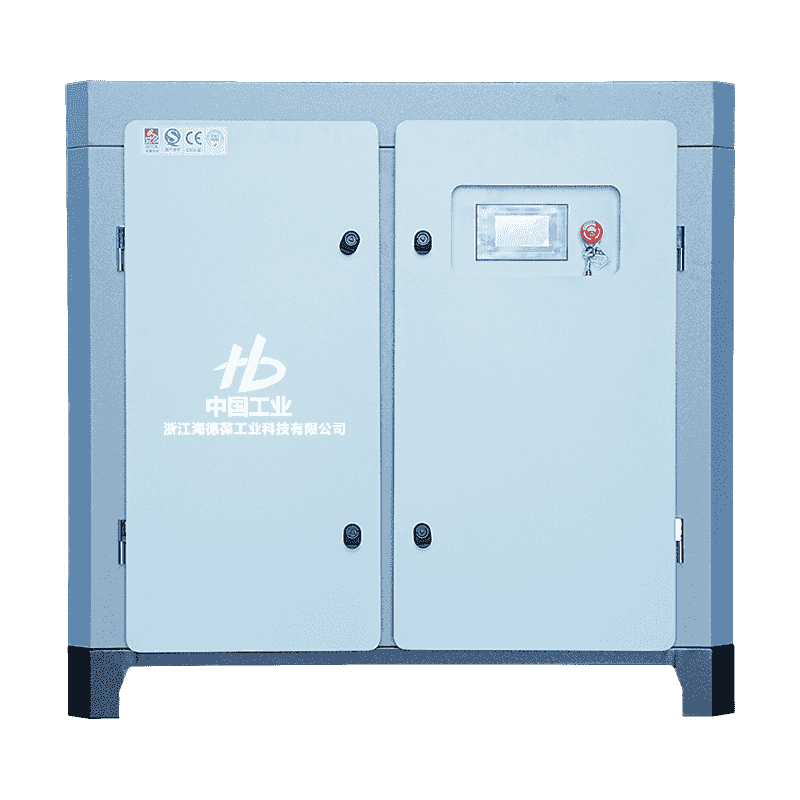

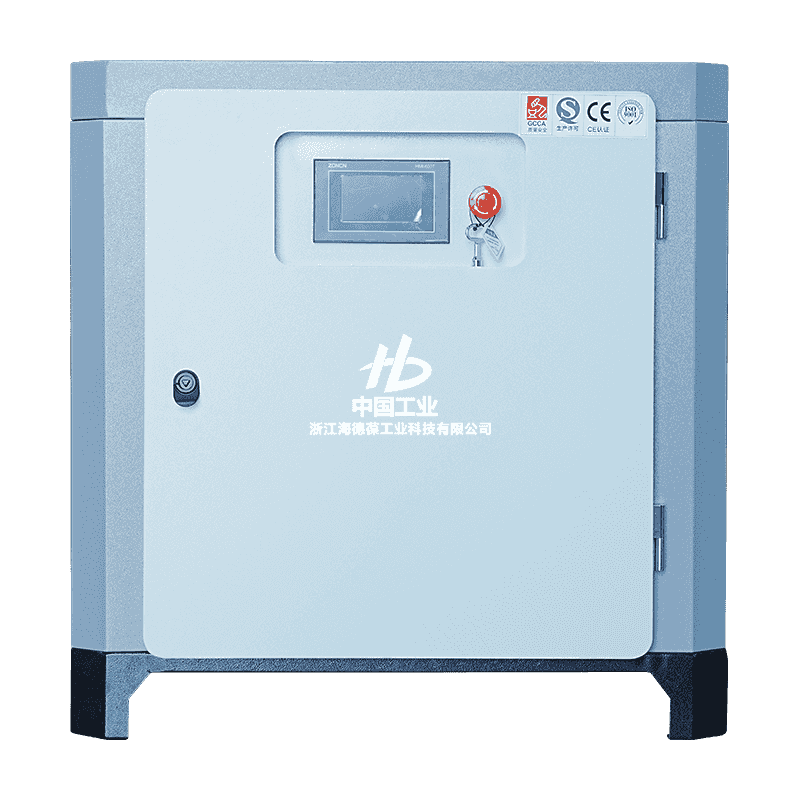

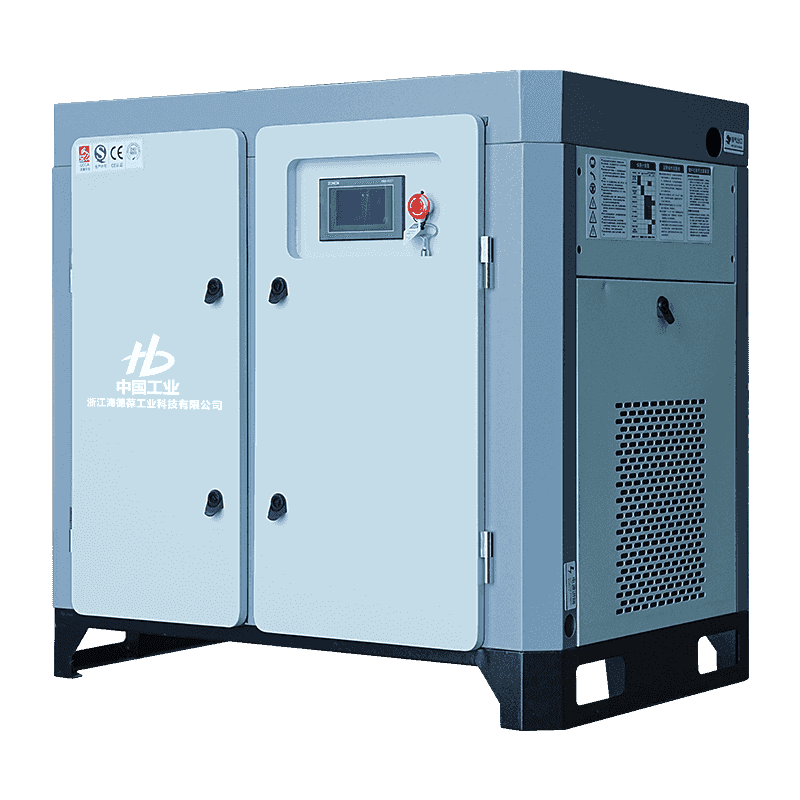

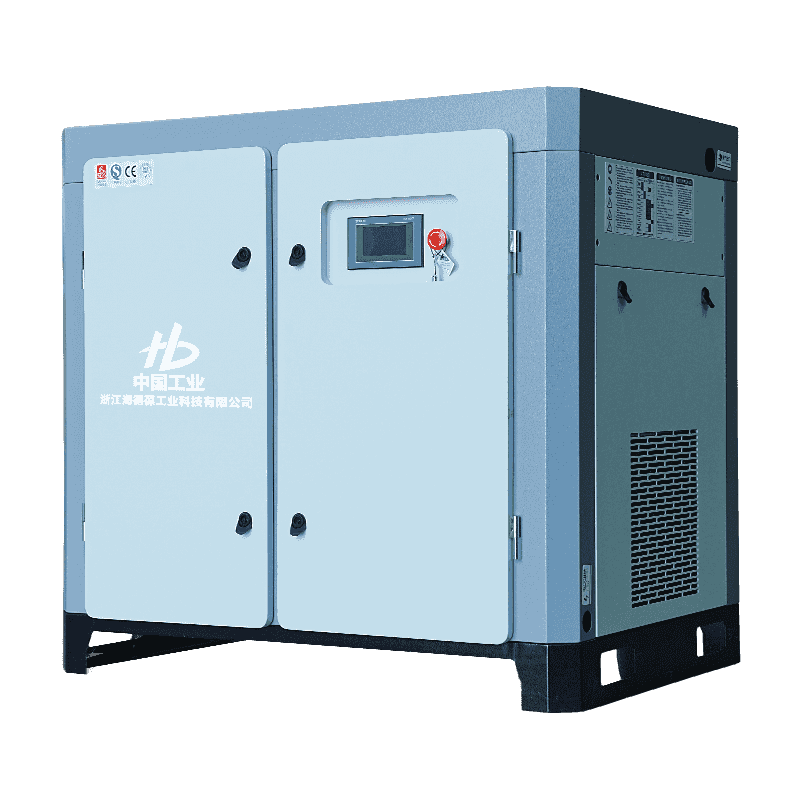

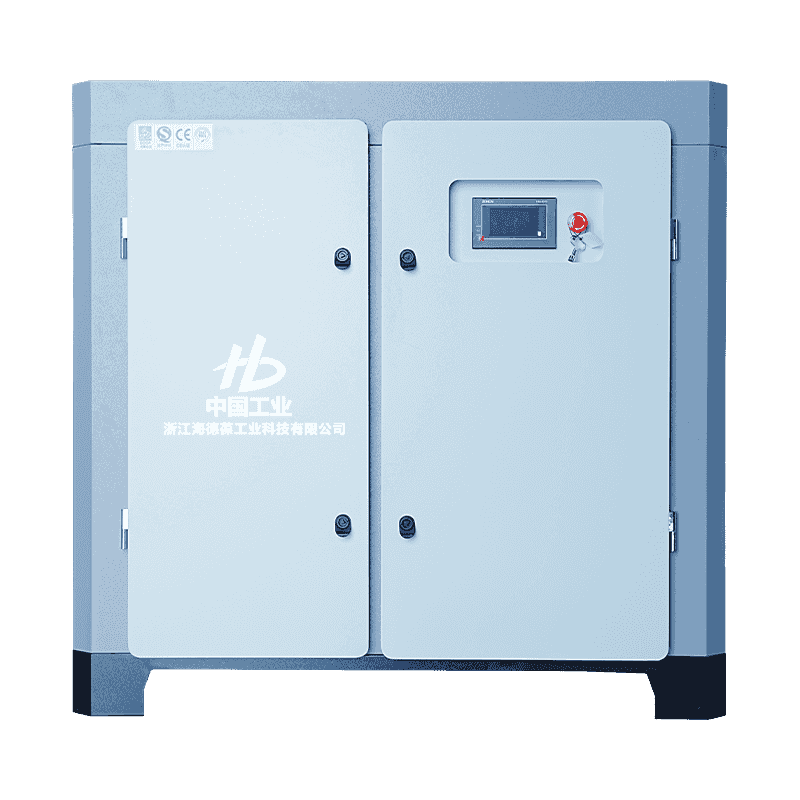

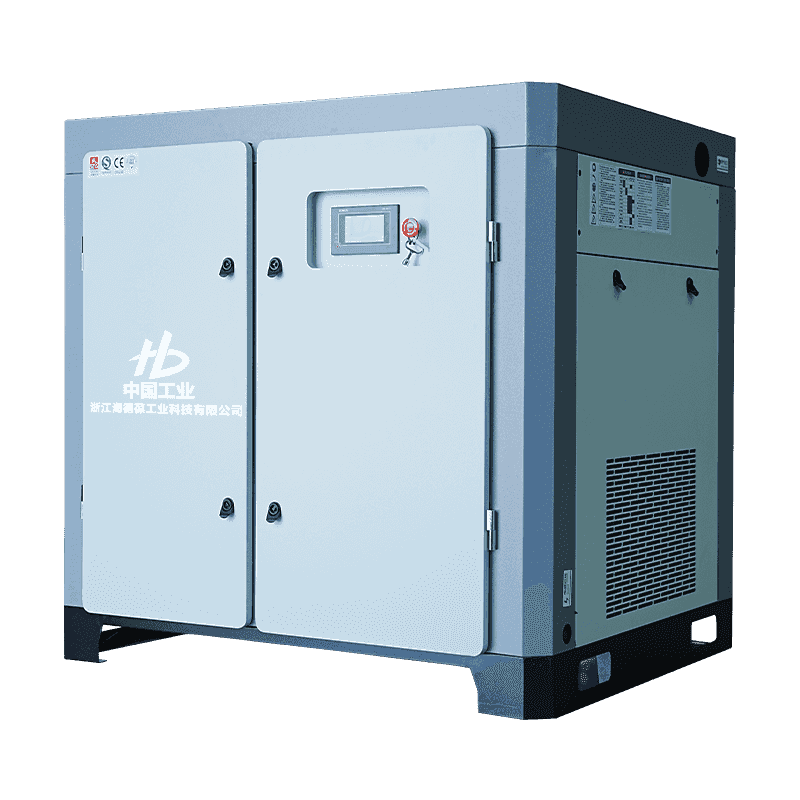

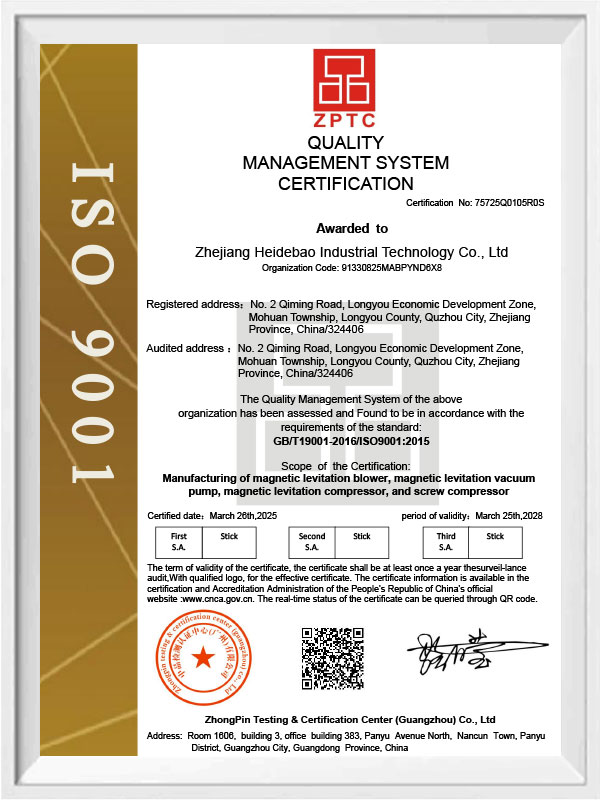

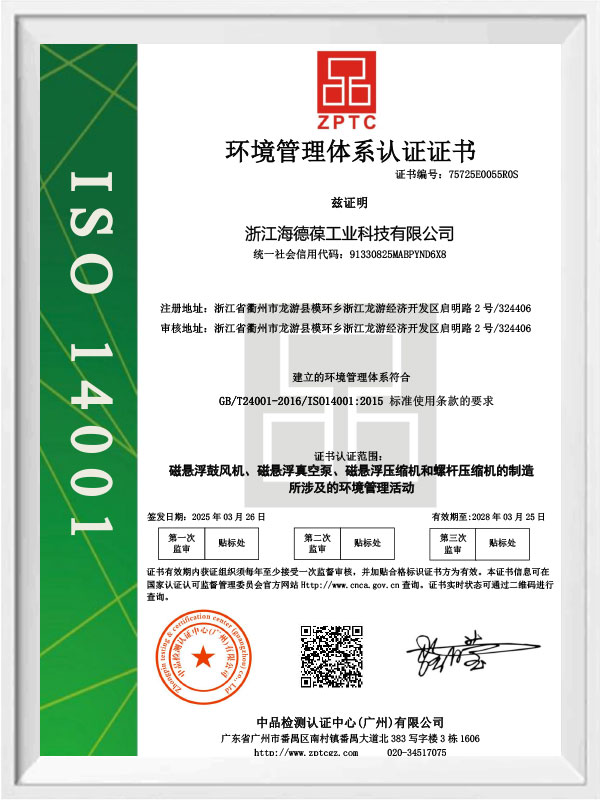

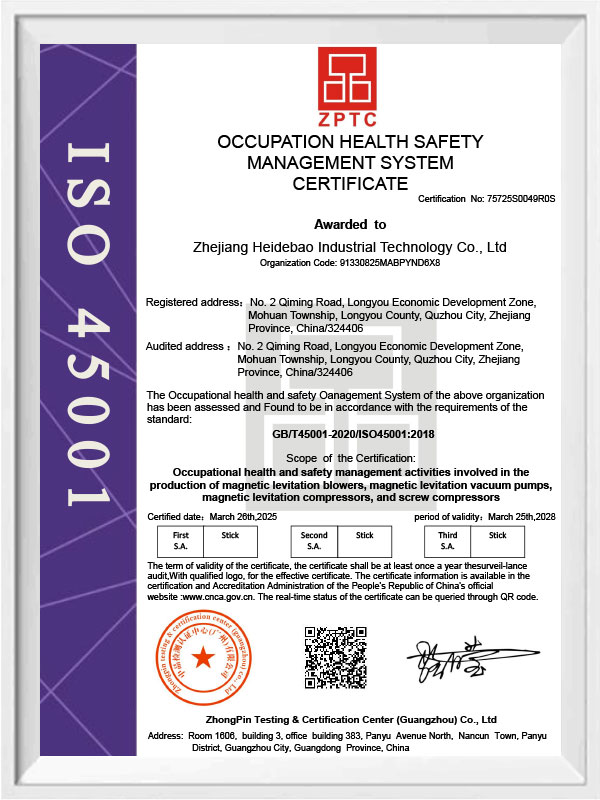

In industrial compressor systems, the presence or absence of a low-vibration base or shock absorption structure significantly influences machine stability, noise control, durability and long-term operating consistency. The 30HP micro-oil twin screw single stage compressor produced by Zhejiang Haidebao Industrial Technology Co., Ltd., located in Quzhou City, Zhejiang Province, integrates multiple system-level design principles aimed at improving operational balance and enhancing overall equipment behavior under varying load conditions. Its integrated structure, permanent magnet synchronous motor and frequency conversion system collectively contribute to vibration reduction, even before additional shock absorption components are considered. Understanding the compressor’s vibration and stability characteristics requires analyzing how each mechanical component interacts within the system and how the company’s design strategy aligns with industrial expectations for low-vibration operation.

Core Mechanical Features That Influence Vibration Behavior

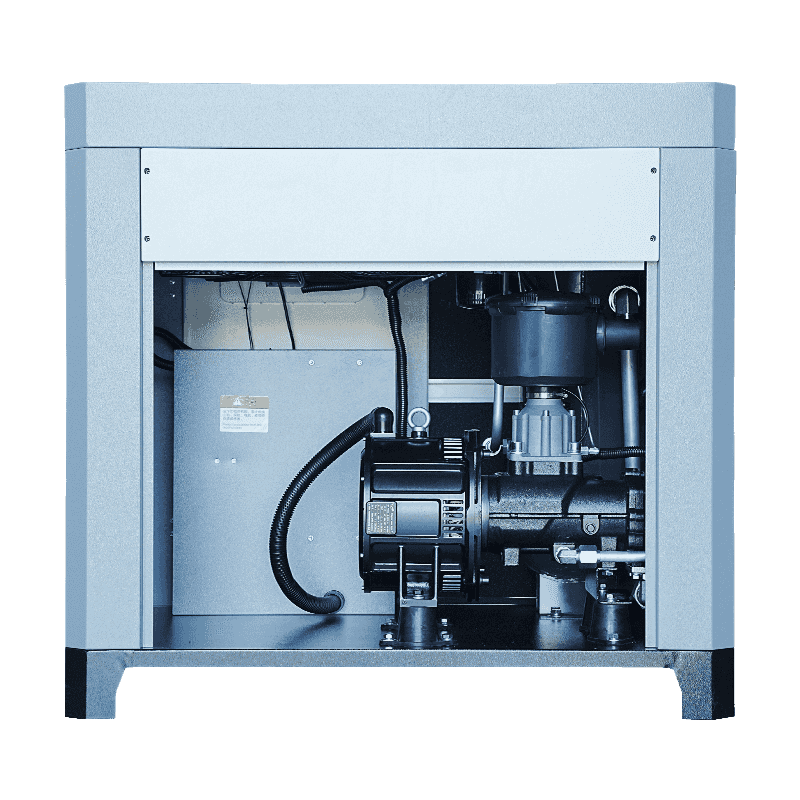

The 30HP micro-oil twin screw single stage compressor incorporates a permanent magnet synchronous motor with low temperature rise protection and a frequency conversion control system, both of which influence vibration characteristics. The direct and efficient interaction between the motor and the screw rotor ensures smooth torque transmission while reducing mechanical oscillation during startup, operation or deceleration. Additionally, frequency conversion technology allows the machine to accelerate and decelerate gradually, minimizing sudden torque spikes that can cause unwanted vibration. The micro-oil lubrication system further stabilizes internal components by reducing friction between moving parts. As a result, although external vibration-absorbing structures may still be needed in certain environments, the compressor’s internal architecture already provides a foundation for balanced and steady running.

| Internal Design Element |

Impact on Vibration |

Operational Benefit |

| Permanent magnet synchronous motor |

Smoother torque delivery |

Reduced oscillation during running |

| Frequency conversion system |

Controlled acceleration and deceleration |

Less mechanical shock |

| Micro-oil lubrication |

Reduces high-friction vibration sources |

Stable rotor behavior |

Potential Low-Vibration Base Design for the 30HP Compressor

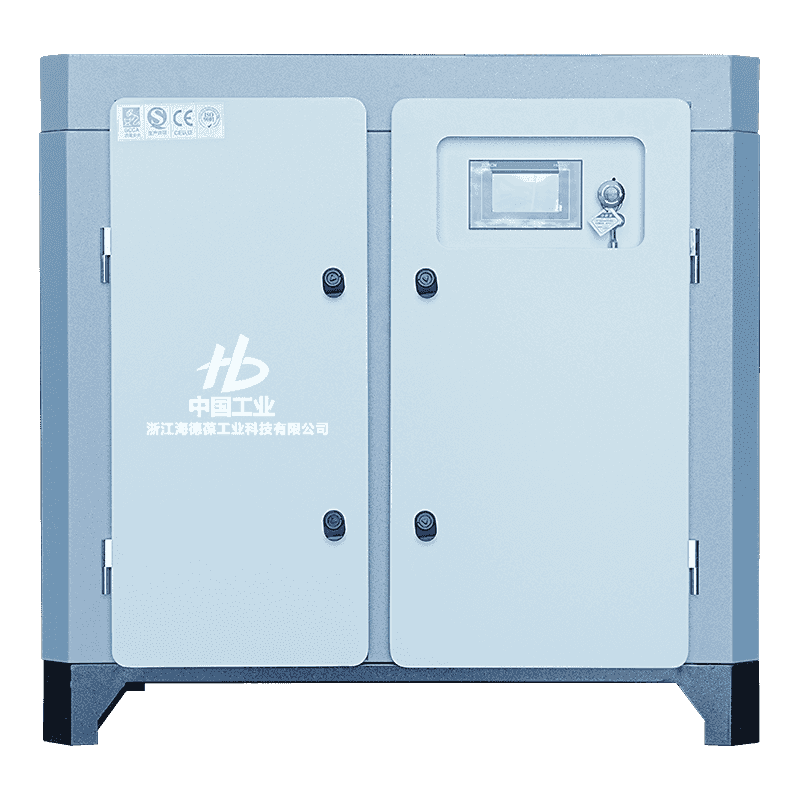

Although specific configuration details may vary depending on the installation environment, many compressors in the 30HP class are engineered with a reinforced base that supports low-vibration performance. In the case of Zhejiang Haidebao Industrial Technology Co., Ltd.’s 30HP micro-oil twin screw single stage compressor, the integrated design approach suggests that the base structure is intended to house internal modules compactly, thereby reducing resonance caused by loosely connected components. The integrated frame also improves overall weight distribution, which is a critical factor in minimizing movement when the compressor is running at high capacity. Even in the absence of externally mounted dampers, a properly engineered housing can greatly reduce vibration transfer to the floor or surrounding equipment, making the compressor suitable for environments where structural vibration control is required.

Shock Absorption Considerations in System-Level Engineering

Shock absorption design in compressor systems often includes rubber mounts, multilayered pads, damping plates or frame-mounted vibration isolators. For a 30HP micro-oil twin screw single stage compressor with a precise frequency conversion system, shock absorption also occurs inherently because the machine does not undergo abrupt mechanical transitions. Additionally, the low-pressure oil separation system—designed with internal baffles, large separation barrels and enhanced separation cores—helps maintain overall system stability by reducing internal turbulence. These elements indirectly contribute to vibration management because pressure stability reduces pulsation forces within the housing. While the compressor may still be compatible with external shock absorption solutions, the system’s internal balance supports reduced reliance on additional vibration control equipment.

| Shock Absorption Element |

Function |

Influence on System |

| Frame-integrated housing |

Reduces resonance and uneven load distribution |

Improves external stability |

| Frequency-controlled motor speed |

Limits sudden mechanical jolts |

Smoother long-term operation |

| Oil separation and lubrication mechanisms |

Stabilizes internal mechanical motion |

Reduces vibration sources |

Operational Scenarios That Benefit From Low-Vibration and Shock Absorption Design

Industrial environments vary widely in terms of structural foundation, noise control requirements and machine proximity. The 30HP micro-oil twin screw single stage compressor is suitable for high-demand environments where low-vibration operation improves the efficiency of surrounding systems. For example, in precision manufacturing facilities, excessive vibration can affect nearby measurement instruments, robotic arms or automated assembly systems. In such contexts, the compressor’s integrated structural design helps maintain operational consistency. In food processing or pharmaceutical applications—common markets for Zhejiang Haidebao Industrial Technology Co., Ltd.—stable airflow and reduced machine movement contribute to cleaner working conditions and smoother production flow. Therefore, even without extensive external vibration-damping accessories, the compressor’s intrinsic engineering provides stability required in these industries.

Comparison of Vibration Behavior With and Without Additional Shock Absorption

While the 30HP micro-oil twin screw single stage compressor exhibits balanced internal mechanics, external vibration control measures may still enhance performance depending on installation conditions. In rigid-floor environments such as reinforced industrial platforms, the compressor’s built-in stability may be adequate. However, in lighter-structure buildings or locations sensitive to vibrational transfer, supplemental shock-absorbing pads or mounts may improve long-term operational comfort. This comparison helps users evaluate whether the machine’s inherent vibration control qualities meet their installation requirements or whether additional vibration-damping elements are needed for optimal use.

| Condition |

Internal Stability Only |

With Additional Shock Absorption |

| Rigid concrete foundation |

Generally stable operation |

Minimal improvement needed |

| Lightweight building structure |

Possible vibration transfer |

Improved isolation recommended |

| Noise-sensitive environment |

Moderate vibration control |

Enhanced comfort and reduced disturbance |

Integration of Structural, Mechanical and Control Technologies

The overall vibration control performance of the 30HP micro-oil twin screw single stage compressor is the result of combined engineering decisions rather than a single design element. The permanent magnet synchronous motor contributes smooth rotational force, the frequency conversion system minimizes sudden mechanical changes, the micro-oil lubrication ensures stable rotor dynamics and the integrated housing supports balanced load distribution. Zhejiang Haidebao Industrial Technology Co., Ltd. incorporates these components to create a compressor suitable for high-demand industrial settings. While the company’s design approach implies that the machine is equipped with a stable, low-vibration foundation, the effectiveness of shock absorption also depends on installation conditions. Users can pair the compressor with external isolation devices if needed, but many industrial installations can rely on the machine’s built-in stability.

English

English Español

Español عربى

عربى